How to Apply Advanced Materials Science in Next-Generation Product Design

In today's rapidly evolving technological landscape, the application of advanced materials science is crucial for developing innovative and high-performance products. This comprehensive guide will walk you through the process of integrating cutting-edge materials into your next-generation product designs, ensuring your B2B offerings remain at the forefront of innovation.

Understanding Advanced Materials

Before diving into the application process, it's essential to grasp the current state of advanced materials science.

• Emerging Trends The field of materials science is experiencing a paradigm shift, with a strong focus on advanced polymers and sustainable solutions[8]. These materials offer unique properties that can significantly enhance product performance and sustainability.

• Key Advanced Materials

1.Nano-engineered materials

2. Smart polymers

3. Carbon-based materials (e.g., graphene)

4. Biomaterials

5. Advanced composites

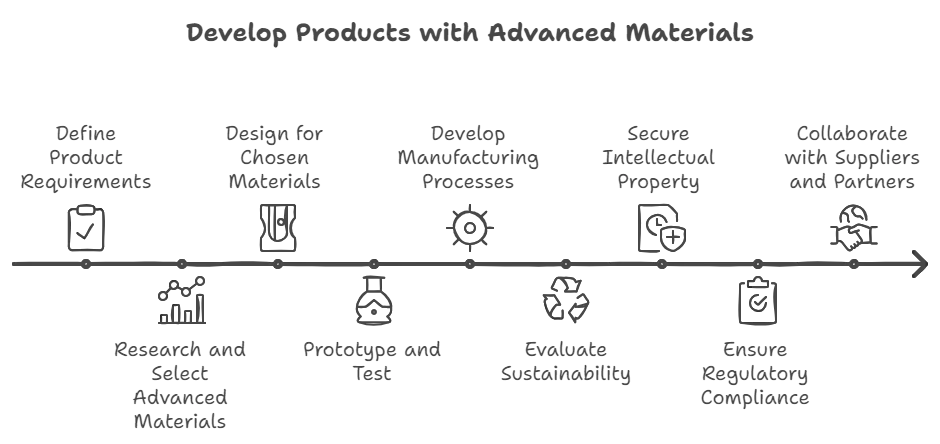

Steps to Apply Advanced Materials Science

1.Identify Product Requirements

Begin by clearly defining the performance requirements and constraints of your next-generation product. Consider factors such as:

1. Mechanical properties

2. Thermal characteristics

3. Electrical conductivity

4. Weight limitations

5. Environmental impact

2. Research and Material Selection

Conduct thorough research to identify advanced materials that align with your product requirements.

1. Review recent scientific literature and patents

2. Attend materials science conferences and exhibitions

3. Collaborate with academic institutions and research centers

When selecting materials, consider their properties, manufacturability, and potential for scalability

3. Design for Advanced Materials

Adapt your product design to leverage the unique properties of the chosen advanced materials.

Design Considerations

1.Optimize geometry for material properties

2.Incorporate multi-functional materials

3.Design for additive manufacturing techniques

4. Prototyping and Testing

Develop prototypes using the selected advanced materials and conduct rigorous testing to validate performance.

Testing Protocols

1. Mechanical stress tests

2. Environmental exposure tests

3. Longevity and durability assessments

5. Manufacturing Process Development

Develop or adapt manufacturing processes to work with the advanced materials effectively.

Manufacturing Techniques

1. Nano-level additive manufacturing

2. Advanced polymer processing

3. Precision machining for composites

Consider the scalability and cost-effectiveness of the chosen manufacturing methods

6. Sustainability and Life Cycle Analysis

Evaluate the environmental impact of the advanced materials throughout the product's life cycle.

Sustainability Factors

1.Raw material sourcing

2.Energy consumption during production

3.Recyclability and end-of-life considerations

Explore opportunities to incorporate waste-derived materials, such as carbon-based electrodes from industrial by-products, to enhance sustainability

7.Intellectual Property Protection

Secure patents for novel applications of advanced materials in your product design.

IP Strategies

1. File provisional patents early in the development process

2. Conduct thorough prior art searches

3. Consider international patent protection

8.Regulatory Compliance and Certification

Ensure your advanced material applications comply with relevant industry standards and regulations.

Compliance Areas

1.Safety certifications

2. Environmental regulations

3. Industry-specific standards

9.Supplier and Partner Collaboration

Establish partnerships with material suppliers, research institutions, and manufacturing experts to support your advanced material implementation.

Collaboration Benefits

1. Access to cutting-edge materials and processes

2. Shared research and development costs

3. Accelerated time-to-market

10. Continuous Improvement and Innovation

Stay updated on the latest advancements in materials science and continuously refine your product designs.

Innovation Strategies

1. Implement a formal materials scouting program

2. Participate in industry consortia and research initiatives

3. Encourage cross-functional collaboration within your organization

Case Study: Advanced RF Packaging

For an example of how this will work, consider the design and production of the next generation of RF packaging for 5G and WiFi 6 applications.

Photosensitive Glass-Ceramics (PSG) have emerged as one of the main substrate materials for RF packaging, finding solutions to SWAP (size, weight, and performance) issues. With PSG engineers are able to

Objectives are as follows: Integration of discrete components and embedded die for passive RF filters; enablement of vertically stacked glass packages for advanced RF SiP systems, allowing higher communications frequencies and greater system integration.

The following case illustrates how the strategic application of advanced materials can lead to significant improvement of product performance and capability.

This comprehensive primer will help B2B companies successfully integrate advanced materials science into the design of next-generation products to innovate and create a market advantage.